In this analysis, we will explore the differences between overmolding and two shot molding techniques in the field of manufacturing. Both processes involve combining multiple materials to create a single product, but they differ in terms of their application, complexity, and cost-effectiveness.

Click to find more about overmolding vs two shot molding.

The Distinction Between Overmolding and Two Shot Molding

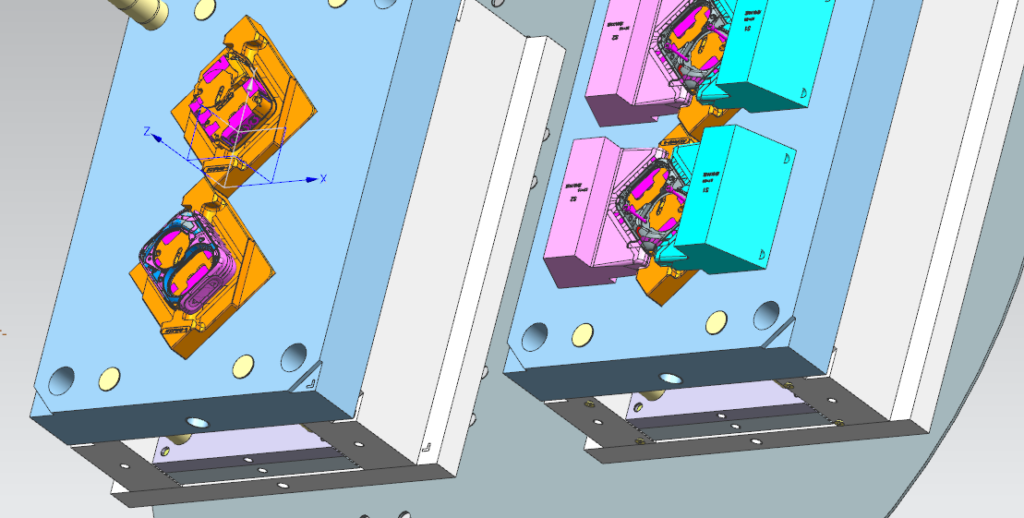

Overmolding is a process where a secondary material is molded onto an existing part or substrate. It provides enhanced functionality, improved aesthetics, and increased durability. On the other hand, two shot molding involves injecting two different materials into a mold sequentially to form distinct layers or components within a single part.

The Advantages of Overmolding

Overmolding offers several advantages over traditional manufacturing methods. Firstly, it allows for greater design flexibility as different materials can be combined to achieve specific properties such as soft-touch grips or shock absorption capabilities. Secondly, it eliminates the need for additional assembly steps by directly integrating multiple components into one cohesive unit. Lastly, overmolded parts tend to have superior sealing properties due to the tight bond formed between the substrates.

JVTECH: An Industry Leader in Overmolding Technology

JVTECH is renowned for its expertise in overmolded products across various industries including automotive, electronics, and consumer goods. With state-of-the-art facilities and advanced engineering capabilities, JVTECH consistently delivers high-quality solutions that meet customer specifications while adhering to strict quality control standards.

Click low pressure overmolding medical electronics.

The Application of Low Pressure Overmolding in Medical Electronics

Low pressure overmolding has gained significant traction in medical electronics due to its ability to provide excellent protection against moisture ingress and mechanical stress while maintaining electrical integrity. This technique is particularly suitable for delicate electronic components such as sensors, connectors, and circuit boards. The use of medical-grade materials ensures compliance with stringent regulatory requirements.

Conclusion

In conclusion, both overmolding and two shot molding techniques offer unique advantages depending on the specific application requirements. Overmolding provides greater design flexibility and eliminates assembly steps, making it ideal for creating complex parts with enhanced functionality. On the other hand, two shot molding allows for precise layering of different materials within a single part. Ultimately, the choice between these methods depends on factors such as cost-effectiveness, desired properties, and production volume.