With the rapid advancement of technology, CNC drilling machines have emerged as a game-changer in the manufacturing industry. These cutting-edge machines offer precision and efficiency like never before, making them highly sought after in various industries. In this article, we will explore the benefits and applications of CNC drilling machines for sale.

Click to find more about cnc drilling machine for sale.

The Advantages of CNC Drilling Machines

CNC drilling machines provide numerous advantages over traditional manual drilling methods. Firstly, they offer unparalleled accuracy and repeatability, ensuring consistent results with minimal errors. This level of precision is crucial in industries such as aerospace and automotive where even slight deviations can lead to catastrophic consequences.

Secondly, these machines are incredibly efficient, significantly reducing production time compared to manual drilling processes. With automated tool changes and high-speed spindle rotations, CNC drilling machines can complete complex tasks swiftly while maintaining quality standards.

Furthermore, these advanced machines are equipped with intelligent software that allows for easy programming and customization. Manufacturers can create intricate designs using computer-aided design (CAD) software and seamlessly transfer them to the machine for precise execution.

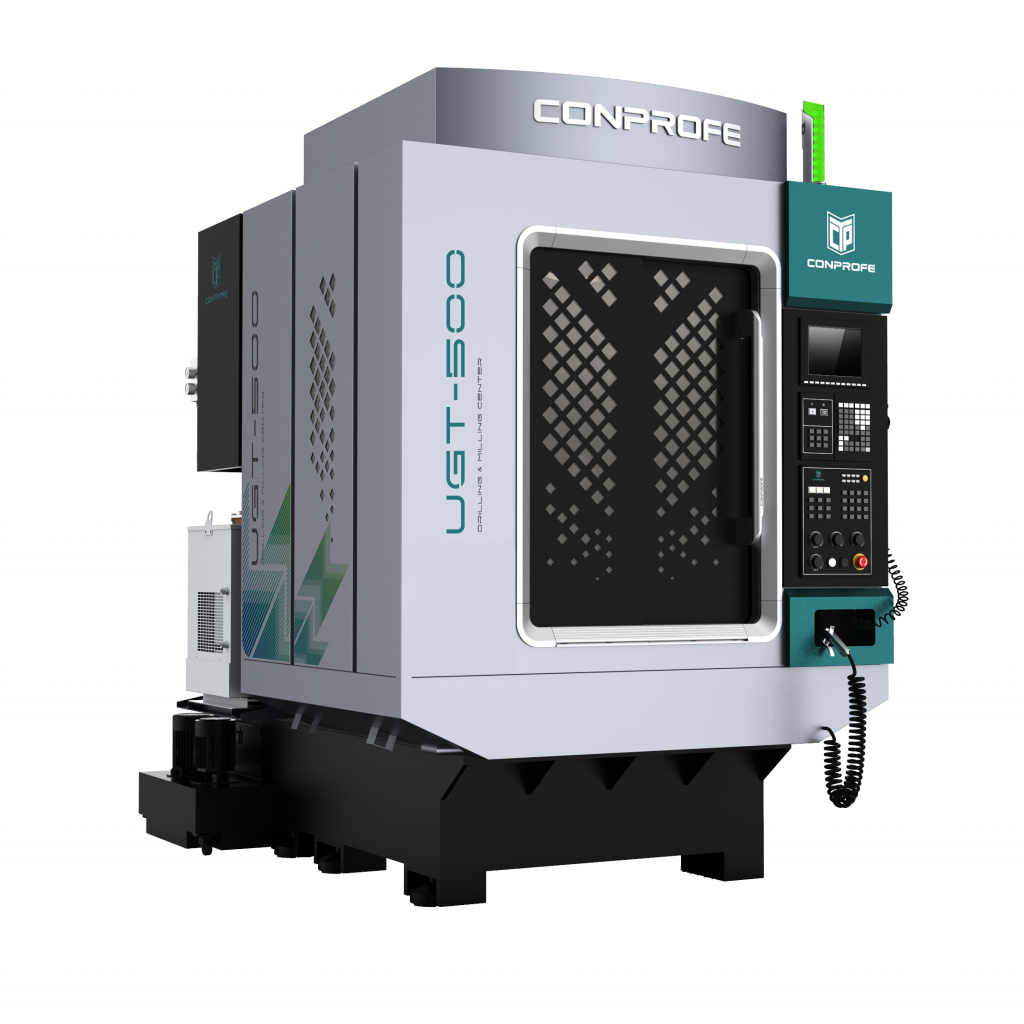

The Role of Conprofe Ultrasonic in CNC Drilling Machines

One notable player in the field of CNC drilling machine technology is Conprofe Ultrasonic. Their innovative ultrasonic drill heads enhance the capabilities of these already powerful machines by enabling faster material removal rates without compromising on accuracy.

The ultrasonic vibrations generated by Conprofe’s drill heads reduce friction between the drill bit and workpiece surface, resulting in smoother cuts with reduced heat generation. This not only extends tool life but also improves overall machining performance.

In addition to improved efficiency, Conprofe Ultrasonic’s drill heads allow for enhanced versatility by enabling drilling in a wide range of materials, including hard metals and composites. This makes CNC drilling machines equipped with Conprofe technology suitable for various industries, from aerospace to medical device manufacturing.

The Role of CNC Milling Service

While CNC drilling machines excel at creating holes and bores, the capabilities of these machines extend beyond just drilling. Many manufacturers also offer cnc milling services alongside their drilling operations.

CNC milling involves removing material from a workpiece using rotary cutters to create complex shapes and designs. By combining both drilling and milling capabilities, manufacturers can achieve greater efficiency and versatility in their production processes.

Whether it’s creating intricate patterns on metal surfaces or producing custom components with tight tolerances, CNC milling service complements the functionality of CNC drilling machines perfectly.

In Conclusion

-1-1024x1024.png)

CNC drilling machines for sale have revolutionized the manufacturing industry by offering unparalleled precision, efficiency, and customization options. With advancements such as Conprofe Ultrasonic’s drill heads and the integration of CNC milling services, these machines continue to push boundaries in terms of what is possible in modern-day manufacturing.

Investing in a high-quality CNC drilling machine not only enhances productivity but also ensures that businesses stay competitive in an increasingly demanding market. Embracing this cutting-edge technology opens up new possibilities for innovation while maintaining stringent quality standards.