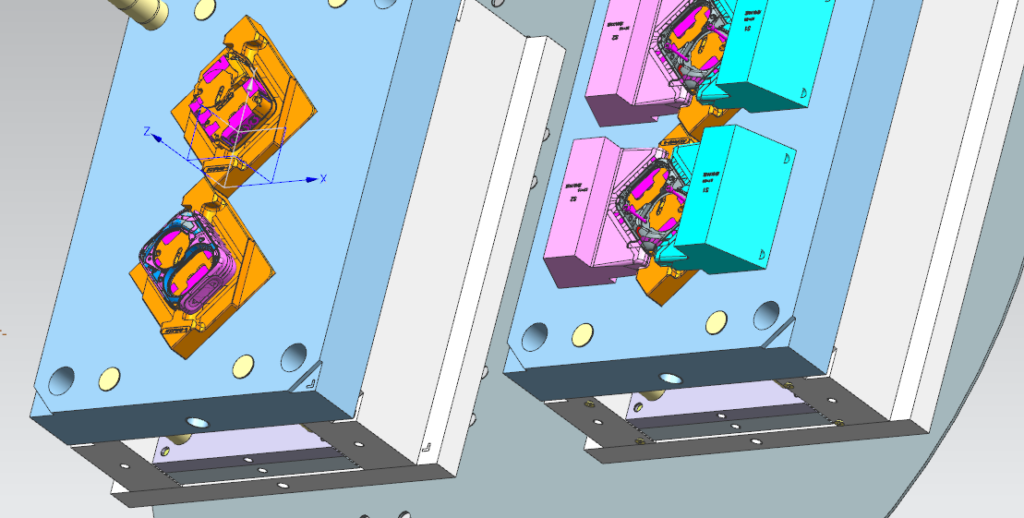

As a leading expert in the field of injection molding, I am excited to share with you the benefits and applications of the innovative 2k injection molding process. This cutting-edge technology allows for the production of complex and high-quality plastic parts by combining two different materials or colors in a single mold.

Enhanced Design Flexibility

The use of 2k injection molding process provides designers with greater freedom to create intricate designs that were previously difficult to achieve. By seamlessly integrating multiple materials or colors into a single part, manufacturers can produce products with enhanced aesthetics and functionality.

Furthermore, this process eliminates the need for secondary assembly operations as different components can be molded together simultaneously. Not only does this save time and cost, but it also ensures better product consistency and reduces potential defects caused by manual assembly processes.

JVTECH: A Leader in 2k Injection Molding

When it comes to reliable and efficient 2k injection molding solutions, JVTECH stands out as an industry leader. With their state-of-the-art equipment and expertise in multi-shot molding techniques, they have successfully delivered numerous projects across various industries.

JVTECH’s advanced machinery enables precise control over material distribution during the injection process. This results in superior part quality with minimal waste material. Their team of experienced engineers works closely with clients from design concept through production to ensure optimal performance and customer satisfaction.

The Role of Medical LSR

In medical device manufacturing, precision is paramount. The integration of medical Liquid Silicone Rubber (LSR) into the 2k injection molding process has revolutionized the production of medical-grade components such as seals, gaskets, valves, and connectors.

medical lsr offers exceptional biocompatibility, chemical resistance, and durability. Its ability to withstand extreme temperatures and harsh sterilization processes makes it ideal for critical medical applications. By combining LSR with other materials in a single mold, manufacturers can create complex parts that meet the stringent requirements of the healthcare industry.

In Conclusion

The 2k injection molding process opens up new possibilities for product design and manufacturing efficiency. With enhanced design flexibility, JVTECH’s expertise in multi-shot molding techniques, and the integration of medical LSR, manufacturers can achieve superior quality products with improved functionality and aesthetics.

As an expert in this field, I highly recommend exploring the potential of 2k injection molding process for your next project. Contact JVTECH today to discuss how their advanced capabilities can bring your innovative ideas to life.